In a world where technology is advancing at an unprecedented pace, predictive maintenance has emerged as a game-changer in the field of industrial maintenance. With the advent of machine learning, predictive maintenance has evolved into a more efficient and cost-effective solution for asset management.

Machine learning algorithms can analyze large amounts of data from industrial equipment and predict potential failures before they occur. This not only reduces downtime and maintenance costs but also ensures that the equipment is running at optimal performance levels.

Table of Contents

In this article, we will explore the various use cases and benefits of machine learning for predictive maintenance and how it can help companies stay ahead of the curve in terms of asset management.

Whether you’re a small business owner or a large corporation, understanding the advantages of machine learning for predictive maintenance can give you a competitive edge in today’s fast-paced industrial landscape.

What is Predictive Maintenance?

Predictive maintenance is a proactive approach to asset management that involves predicting when equipment failure is likely to occur and taking preventative action before it happens.

This approach is based on data analysis and statistical modeling, which allows maintenance teams to identify potential issues before they become major problems. Predictive maintenance relies on the collection of data from industrial equipment, which is then analyzed to identify patterns and trends that can be used to predict future behavior.

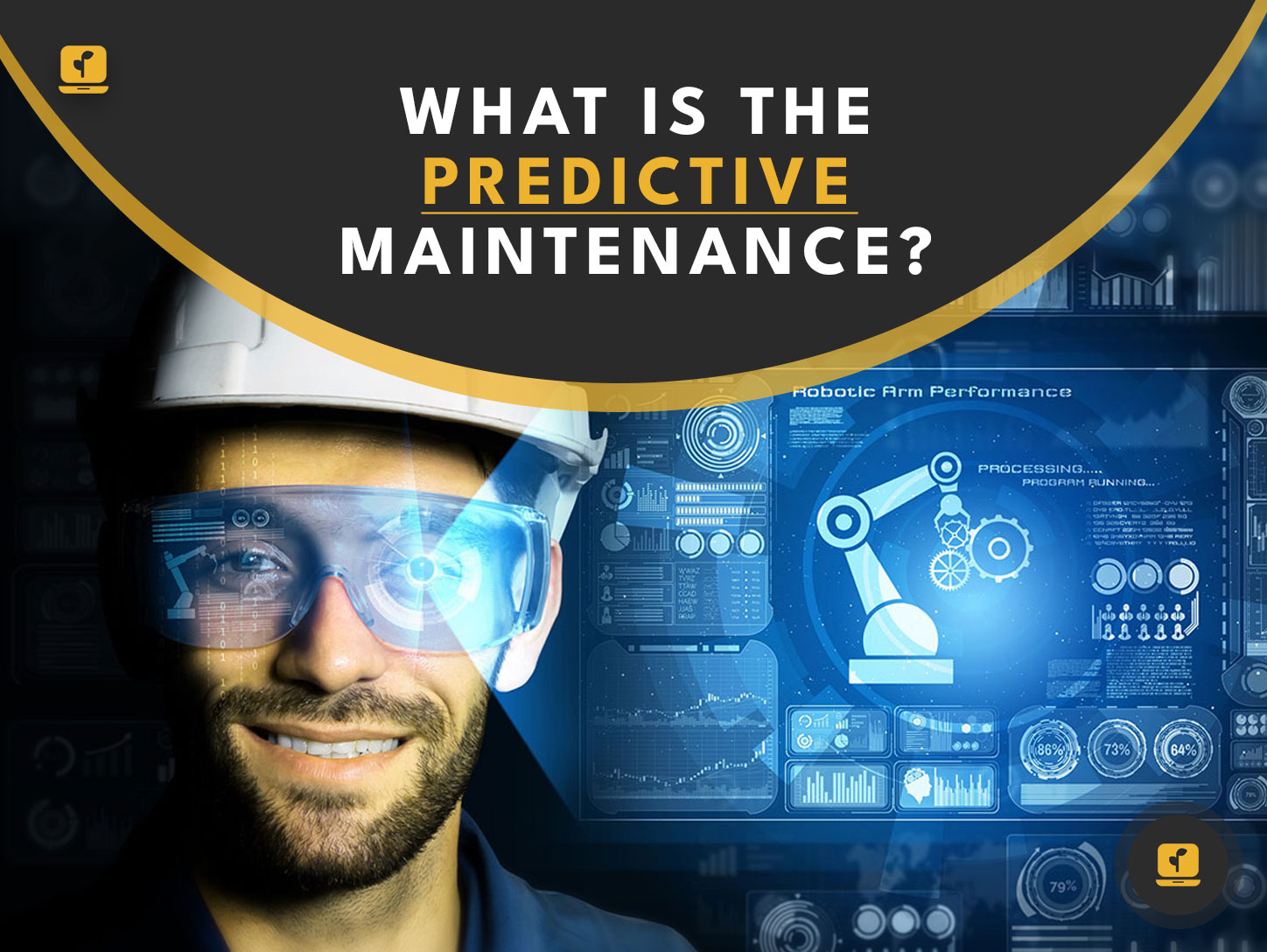

How does Machine Learning Work in Predictive Maintenance?

Machine learning algorithms work by analyzing data from industrial equipment and identifying patterns and trends that can be used to predict future behavior. This is done by feeding historical data into a machine learning model, which then uses that data to identify patterns and make predictions.

In predictive maintenance, machine learning algorithms can be used to analyze data from sensors that are installed on industrial equipment. These sensors collect data on things like temperature, vibration, and pressure, which can be used to identify potential issues before they become major problems. By analyzing this data, machine learning algorithms can identify patterns and make predictions about when equipment failure is likely to occur.

Benefits of Using Machine Learning for Predictive Maintenance

There are several benefits to using machine learning for predictive maintenance. One of the main benefits is reduced downtime. By identifying potential issues before they become major problems, companies can take preventative action to avoid equipment failure. This means less downtime and more uptime, which translates into increased productivity and profitability.

Another benefit of using machine learning for predictive maintenance is reduced maintenance costs. By identifying potential issues early, companies can take preventative action, which is often less costly than repairing or replacing equipment that has failed. This means that maintenance costs can be reduced, which can have a significant impact on a company’s bottom line.

Finally, machine learning can help companies optimize their asset management processes. By analyzing data from industrial equipment, machine learning algorithms can identify trends and patterns that can be used to optimize equipment performance. This can lead to reduced energy consumption, improved efficiency, and increased profitability.

Use Cases of Machine Learning for Predictive Maintenance in Different Industries

Machine learning for predictive maintenance can be used in a variety of industries, from manufacturing to healthcare. In manufacturing, machine learning can be used to predict equipment failure and optimize maintenance schedules. This can help companies reduce downtime and improve productivity.

In healthcare, machine learning can be used to predict when medical equipment is likely to fail. This can help healthcare providers avoid equipment failure and ensure that patients receive the care they need.

In the transportation industry, machine learning can be used to predict when vehicles are likely to require maintenance. This can help transportation companies reduce downtime and ensure that their fleets are operating at optimal efficiency.

Challenges in Implementing Machine Learning for Predictive Maintenance

While machine learning for predictive maintenance offers many benefits, there are also some challenges associated with its implementation. One of the main challenges is data quality. In order for machine learning algorithms to be effective, they need to be trained on high-quality data. This means that companies need to invest in data collection and storage infrastructure to ensure that the data is accurate and reliable.

Another challenge is the need for specialized skills. Machine learning algorithms are complex and require specialized skills to develop and implement. This means that companies need to invest in training and hiring employees with the necessary skills to implement machine learning for predictive maintenance.

Finally, there is the challenge of integrating machine learning with existing asset management processes. This requires a significant investment in time and resources to ensure that the machine learning algorithms are integrated seamlessly with existing processes.

Best Practices for Implementing Machine Learning for Predictive Maintenance

To overcome the challenges associated with implementing machine learning for predictive maintenance, companies should follow best practices. One best practice is to start small and scale up over time. This means that companies should pilot machine learning projects on a small scale and gradually expand them as they become more comfortable with the technology.

Another best practice is to invest in data quality. Companies should invest in data collection and storage infrastructure to ensure that the data is accurate and reliable. This will help ensure that machine learning algorithms are effective and provide reliable predictions.

Finally, companies should invest in training and hiring employees with the necessary skills to implement machine learning for predictive maintenance. This will help ensure that the machine learning projects are successful and provide a positive return on investment.

Future Trends in Machine Learning for Predictive Maintenance

The future of machine learning for predictive maintenance looks bright. As the technology continues to evolve, we can expect to see more sophisticated algorithms that are even more accurate at predicting equipment failure. We can also expect to see more integration with the Internet of Things (IoT), which will allow machine learning algorithms to analyze even more data from industrial equipment.

Another trend we can expect to see is the use of machine learning for prescriptive maintenance. Prescriptive maintenance takes predictive maintenance a step further by not only predicting when equipment failure is likely to occur but also providing recommendations for how to prevent it. This will help companies optimize their maintenance schedules and reduce downtime even further.

Tools and Platforms for Machine Learning in Predictive Maintenance

There are several tools and platforms available for machine learning in predictive maintenance. Some popular options include TensorFlow, Apache Spark, and Azure Machine Learning. These platforms offer a variety of features and capabilities, making it easier for companies to implement machine learning for predictive maintenance.

Case Studies of Successful Implementation of Machine Learning for Predictive Maintenance

There are many examples of successful implementation of machine learning for predictive maintenance. One example is Siemens, which implemented machine learning algorithms to predict equipment failure in its gas turbines. By using machine learning, Siemens was able to reduce downtime and maintenance costs while improving equipment performance.

Another example is GE Aviation, which used machine learning to predict when aircraft engines were likely to require maintenance. By using machine learning, GE Aviation was able to reduce downtime and improve aircraft safety.

Conclusion

Machine learning for predictive maintenance is a powerful tool that can help companies optimize their asset management processes. By analyzing data from industrial equipment, machine learning algorithms can predict when equipment failure is likely to occur, reducing downtime and maintenance costs.

While there are challenges associated with implementing machine learning for predictive maintenance, following best practices can help companies overcome them. As the technology continues to evolve, we can expect to see even more sophisticated algorithms and new applications for machine learning in predictive maintenance.